Overview

Mechanically stabilized earth (MSE) walls have root to prehistoric builders who used sticks and tree branches to reinforce soil structures. The modern use of reinforced soils dates to the 1960s and French architect Henri Vidal’s development of the Reinforced Earth system. In the United States, the first MSE wall was built on California SR-39 near Los Angeles in 1971. A more recent development in MSE walls is the wrapped face wall. This year’s competition will model this development of MSE walls by requiring teams to design and construct a wrapped face retaining wall.

Objective

The objective of the Geo-Wall competition is to design and build a model wrapped faced mechanically stabilized earth (MSE) retaining wall using kraft paper reinforcement. The competition objective is for students to design a wrapped face segmental MSE wall using the least amount of facing and reinforcement material needed to support the retained soil plus both vertical and horizontal (static and dynamic) surcharge loads.

Eligibility

Only one team per school will be allowed to compete. A team consists of a maximum of four (4) students consisting of not more than two (2) graduate students. Each team shall designate a captain who shall be the point of contact for the team. The captain may be an undergraduate or graduate student.

Procedures and Logistics

PRE-COMPETITION CAPTAIN’S MEETING

A team captains’ meeting will be held prior to the competition for the purposes of: checking sandboxes for compliance, establishing competition order, and disseminating any logistical or administrative information. This is a MANDATORY meeting. Each team must have the team captain (or designee) present. All team members are encouraged to attend. Specific meeting time and location will be announced in later Mailers. Teams without a representative at the captains’ meeting will be disqualified.

Teams should bring their sandboxes, PVC piles, and any hardware or tools needed for assembly. Sandboxes and piles will be assembled and checked for compliance at the meeting. Teams will have until 9:15 am local time of the day of the competition to correct any compliance issues identified during the captains’ meeting. All sandboxes must remain at the construction location until your team is scheduled to compete. Any sandboxes or piles found out of compliance at the captains’ meeting will be rechecked at the start of each team’s competition.

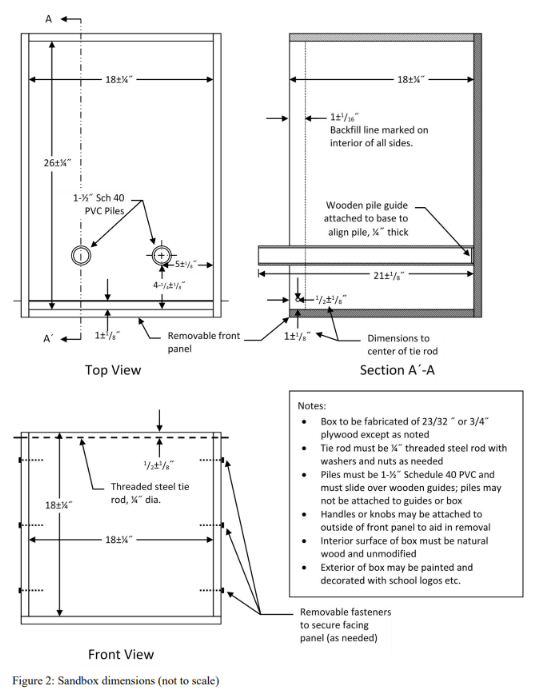

SANDBOX

The wrapped face segmental MSE wall will be constructed within an apparatus hereafter referred to as a sandbox. Each team shall bring their own sandbox to the competition. Painting and addition of school or sponsor logos and other decorations to the exterior of the sandbox is highly encouraged. The sandbox shall be made up of a bottom and four vertical sides with no top. The front panel will be removable as shown in the diagram below. The removable box panel will be in place during wall construction and removed after construction to expose the wrapped face segmental MSE wall. The sandbox will also include two PVC piles used to apply the horizontal load. Dimensions of the sandbox and the PVC piles are shown in the diagrams below. The sandbox will meet the following requirements:

- Have exterior walls and base constructed of any grade of plywood not to exceed 3/4-inch (19 mm) thick.

- Have planar inside surfaces with the natural plywood finish.

- Have a removable front. Panels must be flush with the base of the box and held in place with threaded inserts, screws, hinges or other easily removable fasteners.

- Have a full-sized base such that it extends no more than 3/4 inch (19 mm) beyond the base of the wall once the front panel has been removed.

- Include a steel tie rod designed to keep the two fixed sides of the box parallel after removal of the facing panel.

- Include circular guides to ensure bases of the PVC piles are held in the correct location. A temporary template may be used to control alignment at the top of the piles.

- Any templates used must be removed after wall construction and before testing.

- All dimensions of the sandbox are shown in the diagrams.

For convenience, sandboxes may be designed so they can be transported as flat pieces and reassembled at the competition site. Sandboxes and PVC piles will be checked for compliance at the pre-competition captains’ meeting held the morning of the competition (March 24, 2023). Teams will have until 9:15 am local time the day of the competition to correct any compliance issues. All sandboxes must remain at the construction location until your team is scheduled to compete. Any team with a sandbox and/or PVC piles out of compliance at the start of competition will be penalized.

PILES

Two vertical piles will be used to apply the horizontal load to the backfill behind the wall. Each team will provide their own piles. Piles will be fabricated out of 1-½” schedule 40 PVC pipe. Please see diagram for the pile locations and length requirements.

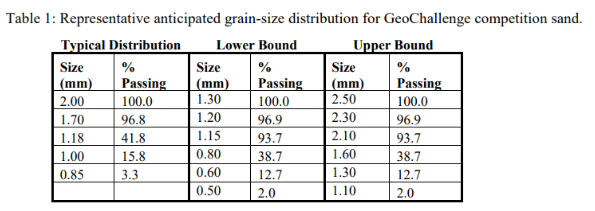

BACKFILL MATERIAL

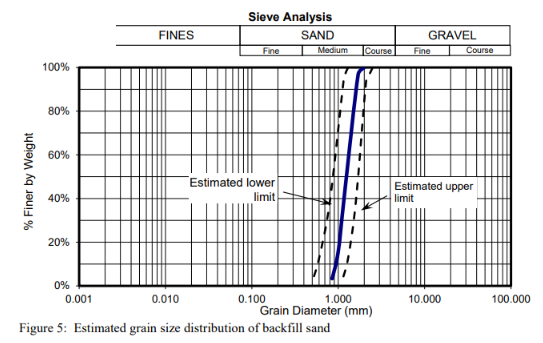

The backfill material will be sand provided by competition organizers on site. The sand will be a clean, dry, rounded to sub rounded sand with grain size as specified in Table 1 and Figure 5. The backfill material must be used as-is: no water, additives, or chemical stabilizers may be placed in the backfill material.

Competition organizers will make reasonable efforts to ensure the competition backfill materials meet the specifications in Table 1 and Figure 5. Teams will be allowed to examine a sample of the competition backfill at the captains’ meeting. No backfill samples may be removed from the meeting room. Teams may modify their wall design at this time if they desire.

WALL MATERIALS

Wall materials will be provided by competition organizers on site. Facing and reinforcement for the wrapped faced segmental MSE wall will be prepared from 60 lb kraft paper. Quantity of kraft paper will be measured by mass to the nearest 0.01g. There are no restrictions on the shape or geometry of reinforcing elements, except that all reinforcement must be cut from kraft paper. Furthermore, each lift of the wrapped faced MSE wall must be segmental at the start of construction. Designs that do not contain segmental lifts at the start of construction will be disqualified.

Teams will be allowed to examine small samples of the reinforcing material at the captains’ meeting. No reinforcing material samples may be removed from the meeting room. Teams may modify their wall design at this time if they desire.

CONSTRUCTION TOOLS

The following construction tools may be used and must be provided by the competing team (quantities of these items shall not be restricted):

- Pencils, pens, and markers

- Rulers and straight edges

- Levels

- Manually operated cutting instruments (e.g., scissors, utility knifes, safety razor blades, hole punch)

- Cutting boards or mats

- Design notes, calculations and drawings

- Material handling and compaction tools consisting of any hand operated devices.

- Screwdrivers (battery operated drills or screwdrivers may be used, but only to remove fasteners when removing the facing panels)

- Temporary templates for use in any stage of competition. These templates may be made of any material, must not have any moving parts, and must be removed at the end of any stage in which they are used.

Buckets and shovels will be provided by the competition organizers. It may be necessary for teams to haul backfill a distance up to 20 feet.

EXECUTION (PROCEDURE)

Construction and testing of the wall will be done in the following stages:

- Reinforcement Fabrication Stage – Each team will be provided with 60 lb kraft paper. The team must fabricate all their wrapped face segmental MSE wall elements from those sheets using authorized construction tools. Twenty (20) minutes will be allotted for this stage. Teams will be penalized for time exceeding the time limit. After all wrapped face segmental MSE wall elements are fabricated, excess material will be disposed of and the judges will weigh the reinforcing elements to the nearest 0.01 grams and measure the length of the reinforcing elements to the nearest inch.

- Construction Stage – After each team’s wrapped face segmental MSE wall elements have been fabricated and weighed, the judges will instruct the team to start construction. At the start of this stage, the wall elements for each lift must be segmental. During this stage the team constructs the wrapped face segmental MSE wall filling the box with sand so that the backfill line (see Figure 2) is covered and the backfill is level, and places the empty 5 gallon vertical surcharge bucket on top of the sand. The facing material must be in direct contact with the inside of the sandbox at all times during this stage. The tie rod may be removed from the box at the start of this stage, but it must be in place before any sand is placed in the box. Temporary templates or guides may be used during this stage so long as they are removed before the end of the stage.

The construction stage is complete when the wall is in place, the sand backfill covers the sand fill line and is level, any temporary templates or guides have been removed, and the empty vertical surcharge loading bucket is in place. Twenty-five (25) minutes will be allotted for this stage. At the end of the phase, judges will check fill placement and the placement of the empty vertical surcharge to ensure that they meet the meets requirements.

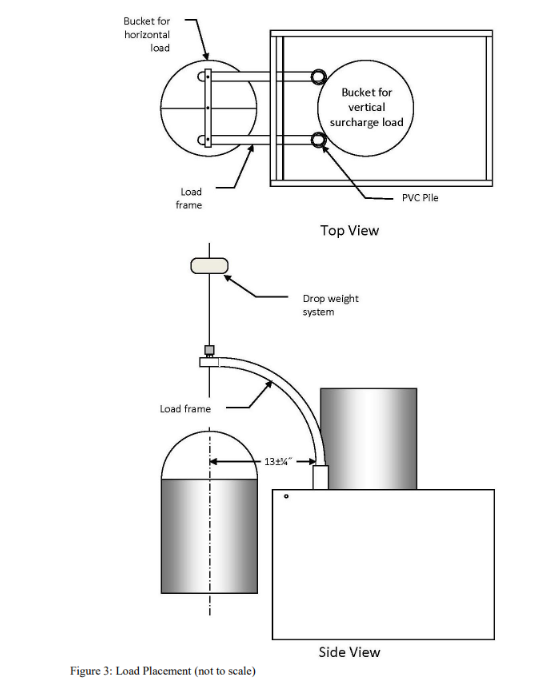

- Loading Stage – Details of the load placement are shown in Figure 3. This stage occurs in three steps: 1) removal of front panel, 2) placement of vertical surcharge, and 3) placement of the static horizontal surcharge followed by a single application of the dynamic horizontal load. During each step, the wall will be checked for the following three criteria: 1) excessive deformation (any portion of the wall extending outside imaginary planes extending vertically from base of sandbox), 2) excessive soil leakage (more than 30 cubic-centimeters of sand passing out of the sandbox), and 3) catastrophic failure. The team will be penalized for excessive soil loss and excessive deformation. The team will be disqualified for a catastrophic failure.

- When directed by judge, the team shall remove the front panel of the sandbox. After the panels are removed, the judge will wait one (1) minute and then check the three criteria.

- If the wall does not fail catastrophically, the team will then place 50 lbs of sand in the vertical surcharge bucket. The team will have one (1) minute to place the load. After the load is placed, the judge will wait one (1) minute and then check the three criteria.

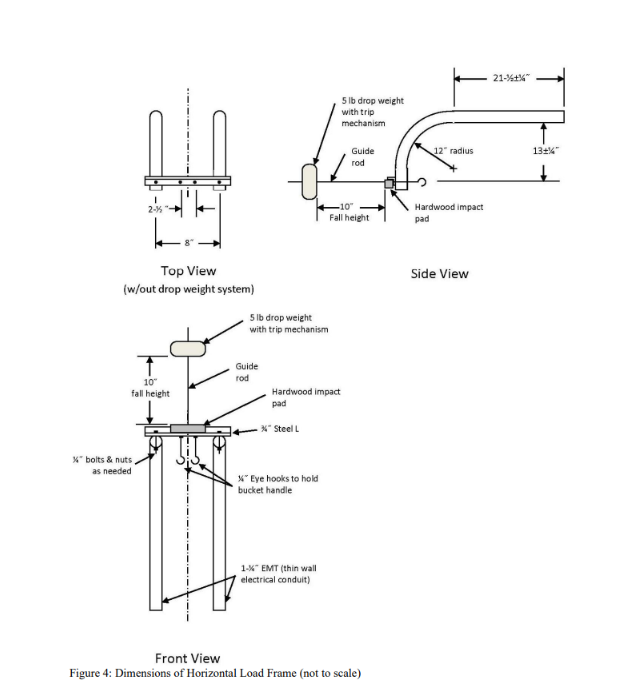

- If the wall does not fail catastrophically, the team will place the 5 lb drop weight on top of the load frame, hang an empty 5 gallon bucket on the loading frame and place 20 lb of sand in the bucket, and then trip the drop weight for a single application of the 5 lb weight falling 10 in. and impacting the top of the loading arm (see Figure 4). The team will have one (1) minute to complete this loading sequence. After the sequence is complete, the judge will wait one (1) minute and then check the three criteria. The horizontal load frame with vertical drop weight will be provided by the competition organizers. Teams should not bring their own load frames to the competition.

Scoring and Judging

For the mass and length of reinforcing MSE Wall elements will be assigned a point score based on linear interpolation. The lowest mass and smallest length will receive the highest number of points, and the highest mass and longest length will receive 50 points in the Mass and Length categories. After completion of the loading stage, the score will be evaluated as follows:

|

Category |

Points |

| Mass of Reinforcing MSE Wall Elements | 100 |

| Average Length of Reinforcing MSE Wall Elements | 100 |

| Total Number of Minutes Over Time Limit for All Phases (Rounded-up to Next Whole Minute) (Subtracted from Score) | Varies |

| Number of Penalties (Subtracted from Score) | 5 |

|

Deflection Rating (Subtracted from Score) |

15 if wall fails deflection criterion during initial loading without surcharge 10 if wall fails deflection criterion during vertical surcharge loading 5 if wall fails deflection criterion during horizontal surcharge loading 0 if wall passes deflection criterion for all loading phases |

|

Total: |

200 max |

- Penalties

- Box dimension out of spec

- Pile guide location out of spec

- Pile dimension out of spec

- Soil leakage greater than 30 cm3 (volume of standard 1 oz plastic medicine cup)

- Any other rule violation that in the opinion of the judges has the potential to provide the team with ant advantage, but does not warrant disqualification

- Disqualification – Teams may be disqualified for the following:

-

- Failure to have segmental lift elements prior to the start of the construction.

- Failure to send a representative to the pre-competition captains’ meeting

- Unsafe practices

- Design or construction techniques which violate the spirit of the competition and provide a large and/or unfair advantage

- Catastrophic wall failure at any point during the loading

Scores will be recorded to the nearest tenth of a point. In the event of a tie the following criteria will be used, in order, to break the tie: 1) lowest actual reinforcement mass, 2) lowest deflection rating, 3) lowest length of reinforcement paper, and 4) judges’ consensus of best decorated box.

The judges will follow the rules as published using reasonable judgment and interpretation. The head judge will be the arbiter of any disputes, which are to be brought forth solely by the Team Captain. Decisions of the head judge are final. Results posted at the competition are not subject to review after the competition.

Competition FAQ

Comments (8)

Mack Johnson

March 13, 2023 at 5:32 pmWhat is the width of the 60lb Kraft paper supplied?

nbohaczyk

March 14, 2023 at 5:45 pm24″

Mack Johnson

March 23, 2023 at 2:41 amIs the length of the paper infinite?

nbohaczyk

March 23, 2023 at 10:52 amThere will be some pre-cut papers available to you, but yes, there is a roll you can cut from that makes the paper length essentially infinite.

Mack Johnson

March 23, 2023 at 4:26 amWhat day and time is the captain’s meeting? It is not specified in the mailer.

nbohaczyk

March 23, 2023 at 10:52 amPlease check the schedule on our website – https://studentsymposium.asce.org/southeast/schedule/. Friday, 8 to 9 AM

Mack Johnson

March 23, 2023 at 8:06 pmThe captains meeting for Geo-Wall is not specified in the schedule. Where is the location of the captains meeting?

nbohaczyk

March 23, 2023 at 8:49 pmGeo-Wall meeting is in the lab area – Building 50.